PDC Bit vs Tricone Bit, Which is The Best Option for You?

PDC Bit is more and more popular these days. When considering all the drilling footage in all industries ( Oil & Gas, Water well, Geothermal, HDD, etc), it takes more than 60%.

PDC Bit cost is becoming less & less, while quality is going up a lot with this relatively new technology mature.

In the right formation & application, PDC can drill as twice fast as a tricone or even more. You can save tons of time & money. But should you change your tricone bit to PDC bits? This article will give you a general idea to start considering.

What is the difference?

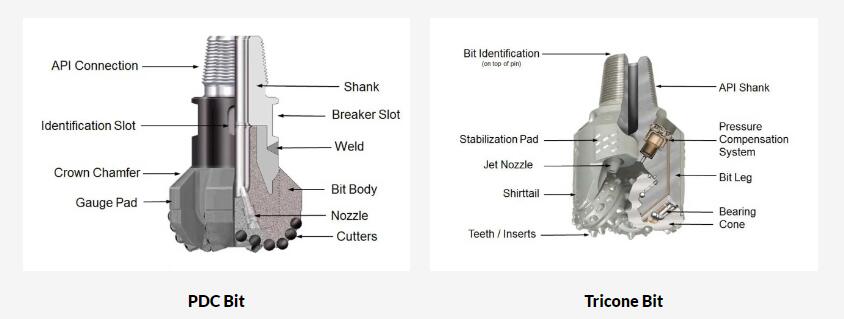

The most straightforward difference is that there is no moving part in PDC Bit. Their structure is as below:

Tricone bits consist of three “cones” which must all rotate on lubricated bearings. This lubrication in turn requires a grease reservoir and for any medium or large-scale project some sort of bearing seal to prevent debris from entering the tricone and stopping rotation.

PDC fixed cutter bits are solid and consist of no moving parts. PDC bits are made by combining fine-grained artificial diamonds and tungsten carbide under extremely high heat and pressure.

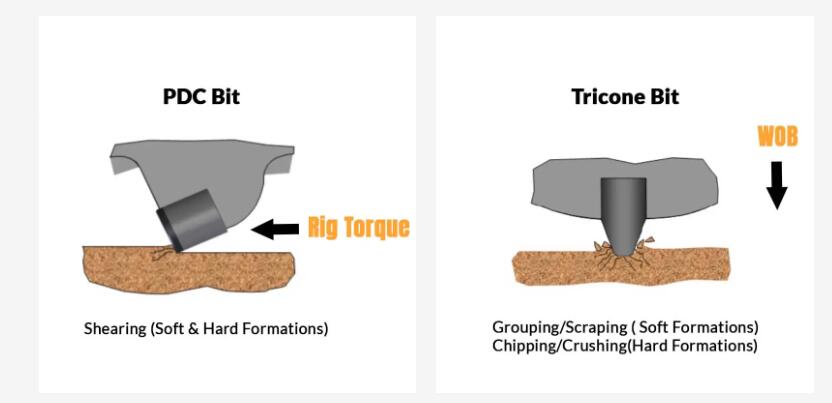

PDC & Tricone cutting type is different as well. PDC is shearing the rock while tricone is grouping, and crushing.

Tricone bit requires relatively higher WOB to perform well. Otherwise, its inserts may prematurely wear out.

Pros & Cons

PDC bits

A. Fast

B. Safe

C. Long lifespan

D. Rebuildable

E. Cutter Breaks in High Impact Formation

The solidity and strength of PDC bits lend them many advantages that a tricone bit can’t match.

Most significantly, PDC bits have a longer lifespan which means they don’t need to be replaced as often as tricone bits. That reason alone explains much of the shift towards PDC bits for large-scale projects.

Additionally PDC bits can achieve a higher Rate Of Penetration than tricone bits under optimal circumstances. These factors combined mean that in formations where the rock type is established and the correct PDC bit is selected you can drill faster and further with a single PDC bit, bringing the cost per foot down below that of a tricone.

Suggested reading:Vane Compressors: The Workhorses of Efficient Air Compression

Advantages of Electric Wheel Loaders

The Laser Cutter Revolution: Transforming Design and Manufacturing

Benefits of Using CNC Rolling Machines for Sheet Metal Fabrication

Even though tricone bits may be cheaper up front, in the right kind of project that can take full advantage of the features of a PDC bit, you will wind up saving money in the long run by going with PDC bits.

Lastly, as tricone bits consist of several different moving parts, it is possible to lose part of the tricone in the borehole, a danger that does not exist with PDC bits.

Tricone Bit

a. Versatile

b. Cost: Initial Low Investment

c. More Control Option

d. Better in Hard Rock Formation

e. More Impact Resistant

f. Slow

g. Possibility to Loss " Cone"

h. Short Lifespan

One of the largest advantages enjoyed by tricone bits is the length of time they have been around. This long stretch of time has allowed the design and manufacture of tricone bits to advance significantly, incorporating advances in material technology such as Tungsten Carbide Inserts, or advances in engineering like sealed journal bearings.

Tricone bits are also easier to control in tricky situations, providing more options in regards to torque and Weight On the Bit.

GRANDDTS Tricone bits are also better for varied rock formations, especially for hard formations. The action of the individual rollers on a tricone bit serves to fracture the rock, making it significantly more flexible in terms of the range of formations one bit can be used on.

One of the most important considerations on any drilling project is always a cost, where all things being equal tricones tend to come out ahead. However, depending on the specifics of the drilling project there may be circumstances that let PDC bits pull ahead.

Conclusion

PDC is an ideal choice for some formation conditions. It works well in consolidated, homogeneous rock, such as shale, sandstone, limestone, sand, and clay.

When your rock as about mentioned, you can try out PDC bit as a fast, safe, rebuttable ( low cost in long run) solution.

Otherwise, Tricone is your best option.

Choose Us-GRANDDTS

GRANDDTS exports PDC Drill Bits, Tricone Drill Bit, and Oil Drilling Bit, we have a whole set of quality management systems. If you have interested in our products, pls feel free to contact us.

Introduction to Wheat Flour Milling Plant: A Comprehensive Guide

Air-Cooled Screw Condensing Units